CERAMIC MEMBRANES AND FILTRATION TECHNOLOGIES

We at Biosnar manufacture ceramic membrane filtration technologies offering you our expertise and top-quality products. Our Biosnar specialists offer you a comprehensive consultancy service and supply of ceramic membranes, housings, modules, racks, systems and solutions.

Avail of our fully guaranteed professional support, from a detailed study of your needs, selection of the optimal ceramic membranes for your project, support and the professional assistance provided by our team.

Please contact our team if you are looking for tailored advice to help you select ceramic membranes for your project. We are here to answer any queries you may have.

WHAT ARE CERAMIC MEMBRANES?

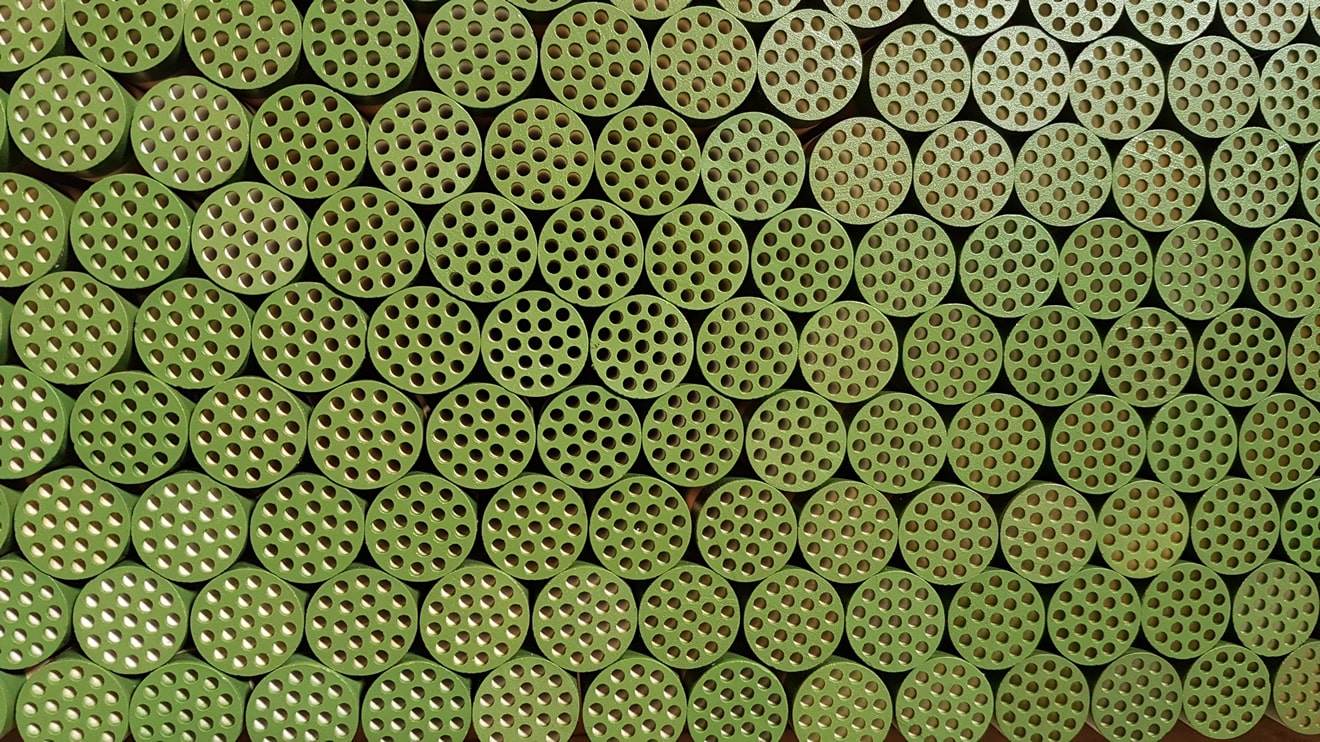

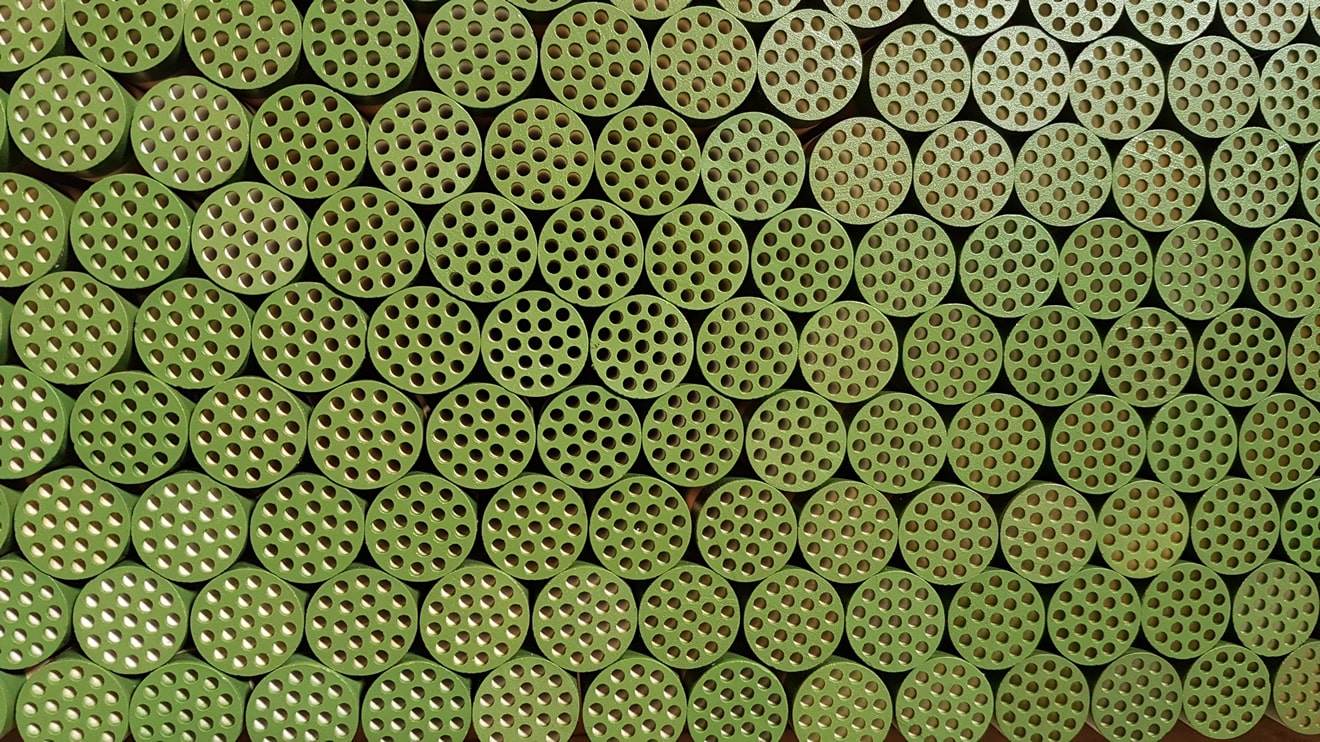

Ceramic membranes are ceramic material filters, usually metal oxides, Al2O3, TiO2, ZrO2, SIC, etc., characterised by their excellent mechanical, chemical and thermal properties, making them ideal in any filtering, purification, separation and concentration process in the industrial sphere.

WHAT TYPES OF CERAMIC MEMBRANES ARE ON THE MARKET?

Apart from inorganic material, ceramic membranes can also have a wide pore size spectrum from 1 micron to < 500 daltons across the entire MF, UF and NF range. They can also have several tubular geometries, flat geometries and discs, and can be applied in pressure intensive processes/crossflow speed, extensive vacuum filtration low-pressure processes and a combination of both including rotation in the case of discs.

WHAT ARE CERAMIC MEMBRANES USED FOR?

Ceramic membranes are used in any separation, purification and/or concentration process. In water purification, filtration and separation of effluents and fluids in industry, oil & gas, food and pharmaceutical processes, etc. Its excellent mechanical, chemical properties and its precision in terms of pore size offer amazing opportunities in industrial applications, as well as in water treatment and purification.

HOW IS A CERAMIC MEMBRANE MANUFACTURED?

They are membranes composed of a macroporous support and one or more microporous layers. Their asymmetrical structured multilayer structure is usually obtained by extrusion, pressing or bonding. Immersion and dip coating are the most common methods for layer deposition.

HOW DO I CHOOSE A CERAMIC MEMBRANE SUITABLE FOR MY PROJECT?

We at Biosnar study the needs of your company or project to provide you with the best ceramic membrane solutions to meet these needs. We are manufacturers and specialists in consultancy for ceramic membranes for the filtration of water and many different types of industrial fluids. Contact our team.